Reverse Engineering

Accurate 3D Scanning and Modeling for Existing Parts

Overview of Reverse Engineering

At Mechanical DesignHub, our reverse engineering services provide accurate 3D scanning and modeling for existing parts. Reverse engineering is a vital process for many industries, enabling the recreation and analysis of existing components to enhance or replicate their design. Our expert team uses cutting-edge scanning technology to capture the precise geometry of your parts, transforming physical objects into detailed digital models. This process is invaluable for understanding the intricacies of complex parts, developing improvements, or creating duplicates when original drawings are unavailable. Whether for legacy parts, competitor products, or custom components, our reverse engineering services deliver the accuracy and detail needed to meet your project goals.

Advanced 3D Scanning Technology

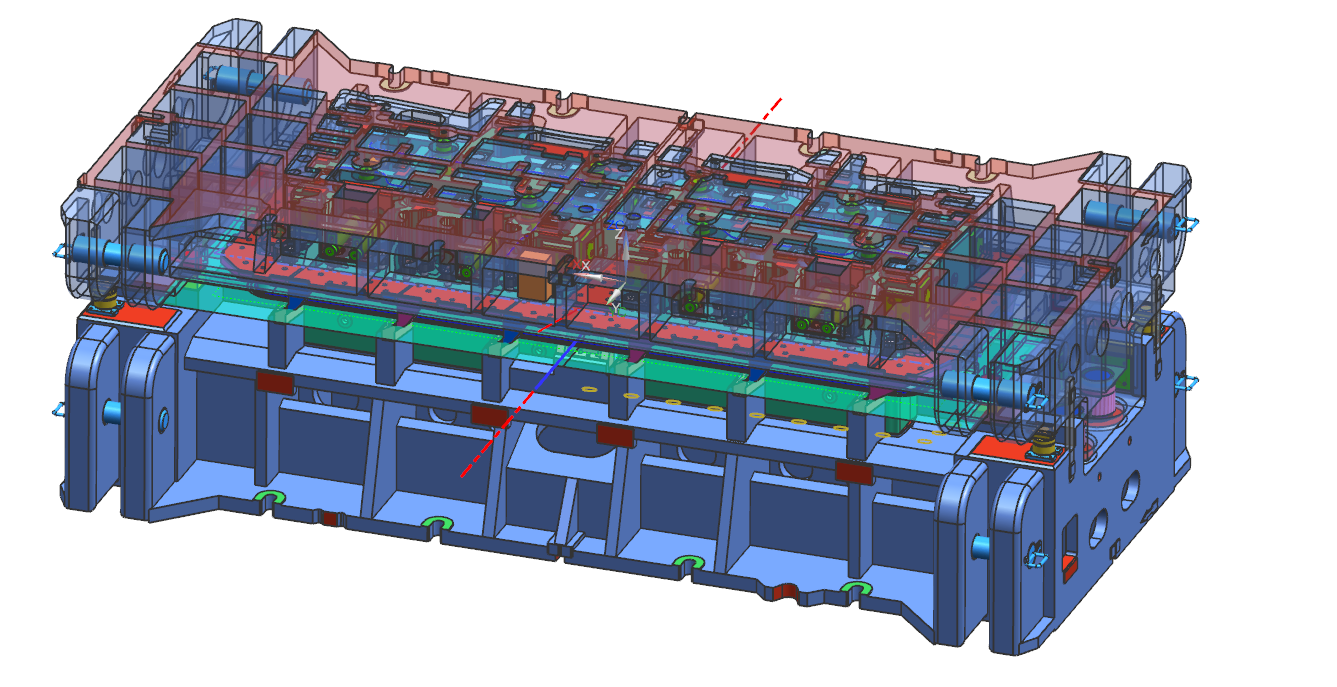

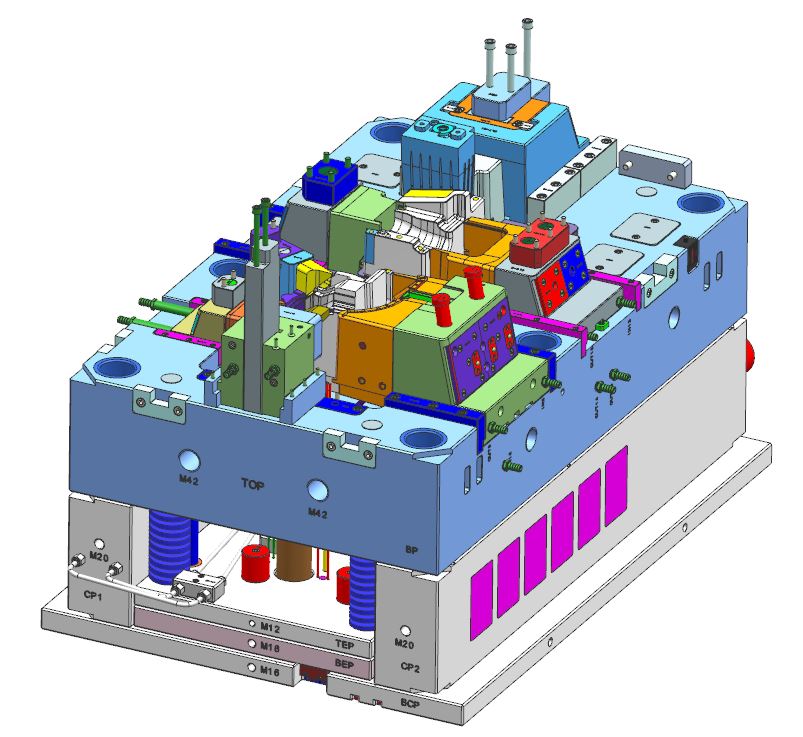

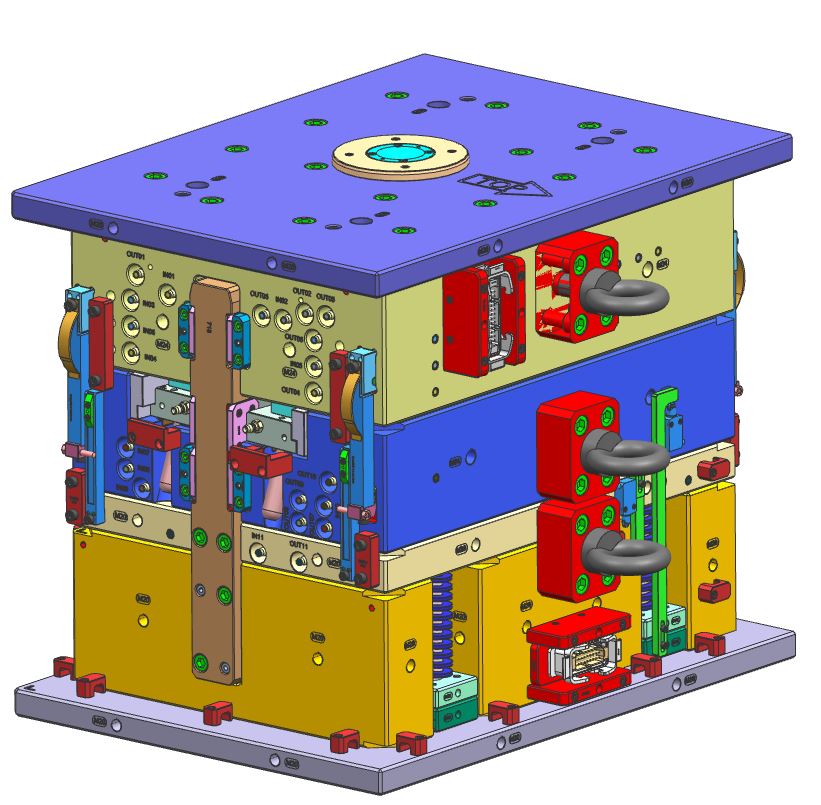

Our reverse engineering process begins with advanced 3D scanning technology, which captures the exact dimensions and features of your parts. We use high-resolution scanners that can handle a wide range of sizes and materials, ensuring that every detail is accurately recorded. The scanned data is then processed to create a precise 3D model of the component. This model can be used for various purposes, including analysis, redesign, and manufacturing. Our state-of-the-art scanning equipment ensures that we capture even the most intricate details, providing a comprehensive digital representation of the physical object. This high level of accuracy is essential for creating reliable and functional replicas or improvements.

Detailed Analysis and Modeling

Once the 3D scan is complete, our team performs a detailed analysis of the captured data. We utilize advanced software to clean and refine the scan, ensuring that the resulting model is free from errors and accurately represents the original part. This digital model can then be used for various applications, including finite element analysis (FEA), computational fluid dynamics (CFD) simulations, and direct manufacturing. Our detailed modeling process ensures that every aspect of the part is accurately captured, from complex geometries to fine surface details. This comprehensive approach allows for thorough analysis and modification, enabling you to understand the part’s functionality and identify potential improvements.

Applications and Industry Solutions

Our reverse engineering services cater to a wide range of industries and applications. In the automotive sector, we help recreate and enhance components for improved performance and reliability. In aerospace, our services are used to analyze and replicate critical parts, ensuring safety and efficiency. For industrial machinery, we provide accurate models of legacy parts that may no longer be available, facilitating maintenance and upgrades. Additionally, our reverse engineering services are valuable in consumer product development, allowing for the enhancement of existing designs and the creation of custom solutions. No matter the industry, Mechanical DesignHub offers tailored reverse engineering solutions that meet your specific needs and drive innovation and success.

Ready to Elevate Your Project?

Partner with Mechanical DesignHub and experience the difference our expertise can make. Whether you need cutting-edge CAD designs, advanced CFD analysis, stunning renderings, or precise reverse engineering, we are here to help.